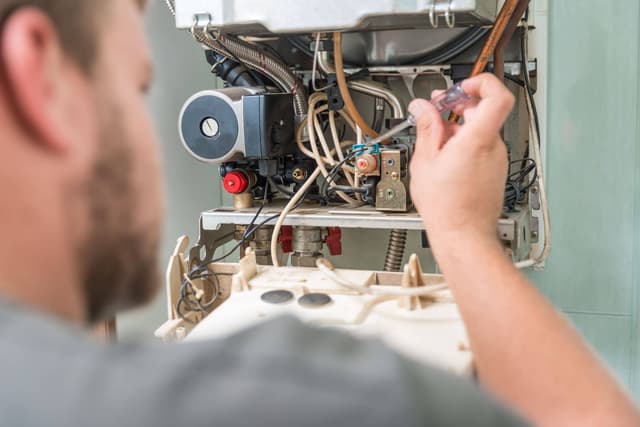

Forced Air Units (Repair, Retrofits, and Replacement Services): Essential HVAC Solutions for Your Home

Understanding Forced Air Units

Forced air systems are a crucial component of many home heating and cooling setups within an HVAC system. These versatile units efficiently distribute conditioned air throughout a building using a network of ducts and vents.