Understanding Makeup Air Units

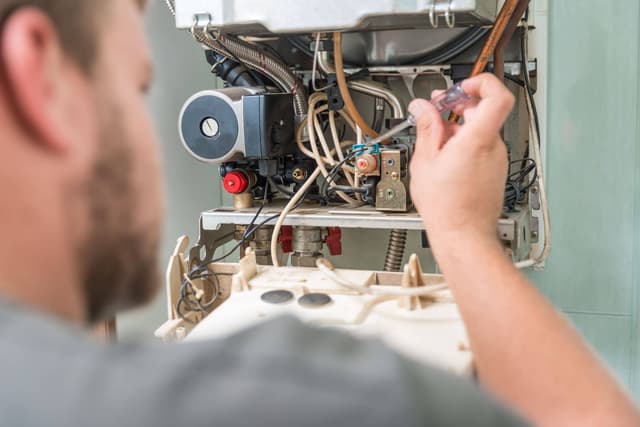

Makeup air units play a crucial role in maintaining indoor air quality by providing replacement air that balances building pressure. By compensating for air exhausted from the HVAC system, these units help prevent issues like negative air pressure.